Mahindra Aerostructures

A global player in aerospace components and assemblies

Previous

Next

Our Capabilities

Driving innovation in Aerospace and Defence

Previous

Next

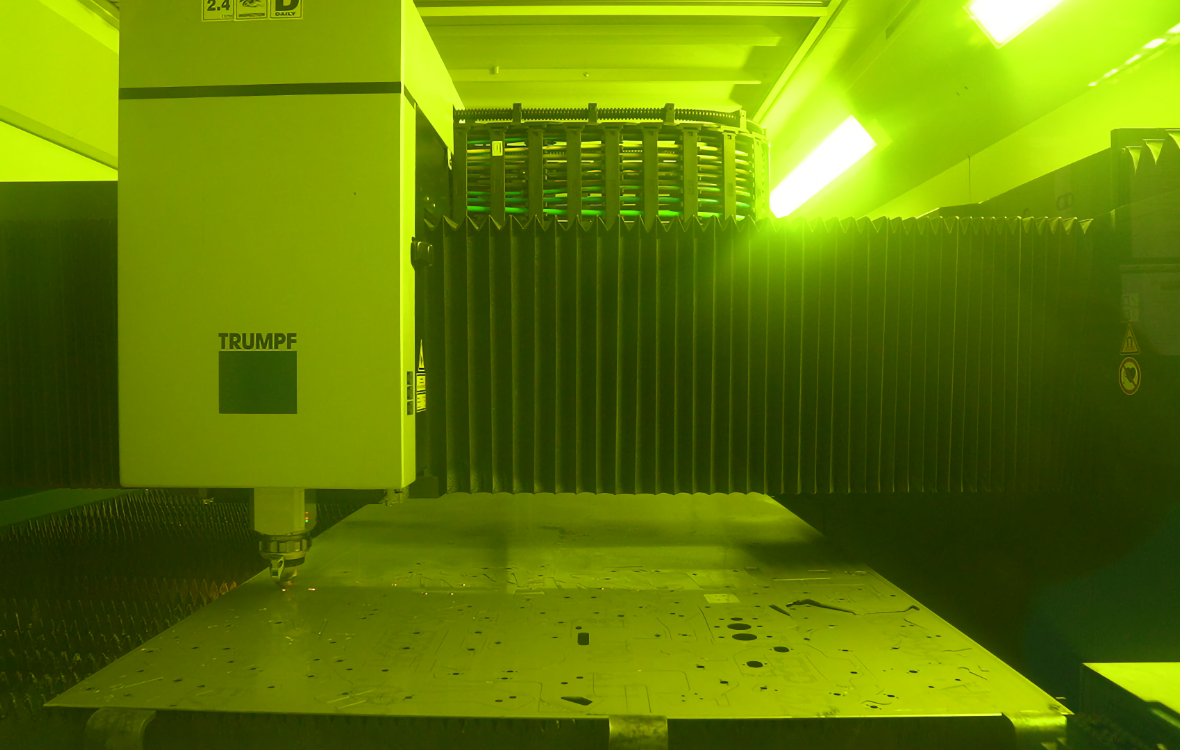

CNC – Profile Cutting

- Routing : single & dual spindle (4 m x 3 m and 4 m x 2 m) – soft metal

- Laser cutting (3 m x 1.5 m and 4 m x 2 m)- hard metal

Automated Deburring

- Fladder – soft metal

- Grindmaster – hard metal

- Rosler Vibro-deburring

Forming

- NC brake presses (up to 3 m working length, Tonnage: 25 to 100 T)

- Rubber press (2000 T & 2750 T)

- Stretch forming: skins (Hufford 50 T) & extrusions (Hufford 60 T)

- Stretch forming (Future addition): skins (ACB FET400) & extrusions (ACB FEV30)

- Deep drawing press (150 T)

- Rolling machine (up to 6 m rolling length)

- Beam straightening (200 T) presses

Previous

Next

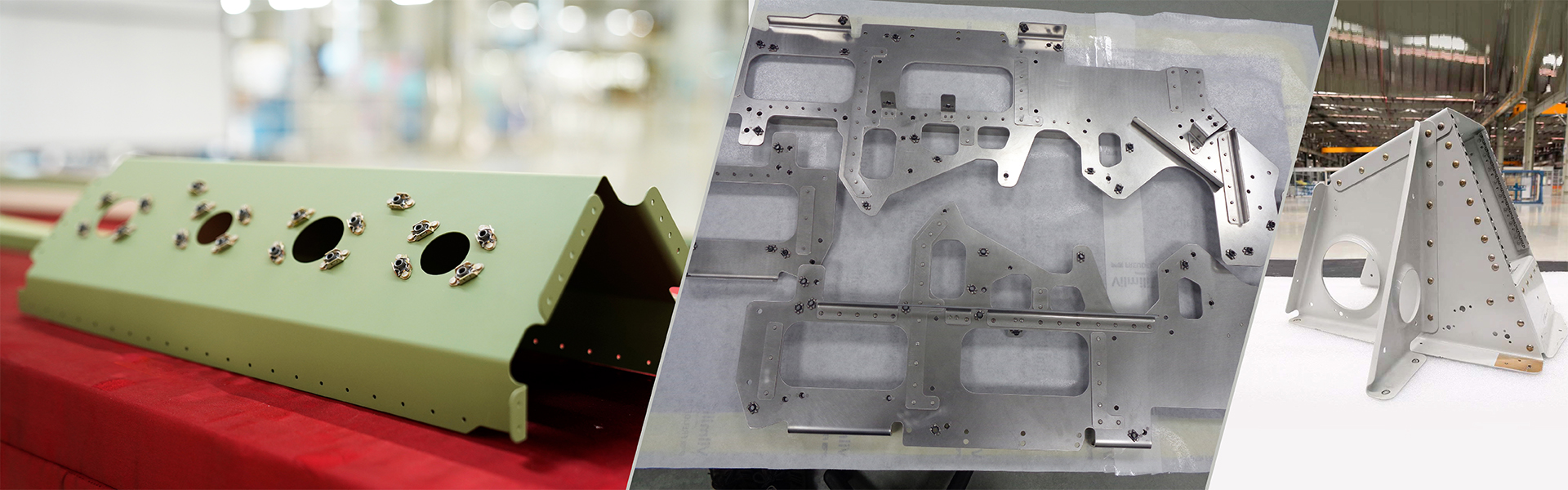

Machining of components up to 3 m long

Raw Material: Aluminum, Titanium, Stainless Steel, Inconel

5 Axis Machine :

- Doosan VCF (X – 3 m, Y – 0.85 m, Z – 0.8 m)

- Doosan BM2035U (X – 3 m, Y – 0.85 m, Z – 0.8 m)

- Belotti (X – 2.6 m, Y – 1.7 m, Z – 1.3 m)

3 Axis Machine :

- BFW Virat 1530 (X – 3 m, Y – 1.7 m, Z – 1 m)

- Doosan DNM 750 (X – 1.63 m, Y – 0.76 m, Z – 0.65 m)

- DMG MORI (X – 1.45 m, Y – 0.7 m, Z – 0.55 m)

- BFW BMV 60 TC20+ (X – 1.05 m, Y – 0.61 m, Z – 0.61 m)

- AMS (X – 0.7 m, Y – 0.4 m, Z – 0.32 m)

|

Process

|

Type

|

Make

|

Working Dimensions (LxWxH)

|

|---|---|---|---|

|

Annealing / Solutionizing (soft metal)

|

Drop Bottom Furnace

|

AIFL

|

3.8m x 1.8m x 1.9m

|

|

Annealing / Solutionizing (soft metal)

|

Drop Bottom Furnace

|

High Temp Furnaces

|

1.5m x 1.5m x 1m

|

|

Ageing (soft metal)

|

Ageing Oven

|

Therelek

|

5.9m x 1.7m x 1.7m

|

|

Ageing (soft metal)

|

Ageing Oven

|

Furnace Engineering

|

1.3m x 1.2m x 1.6m

|

|

Heat treatment (hard metal)

|

Muffle Furnace

|

Argo Thermodyne Co.

|

0.9m x 0.9m x 0.9m

|

|

Cold Storage

|

Freezer Cabinet

|

Carrier

|

9.3m x 6.3m x 4.4m

|

Previous

Next

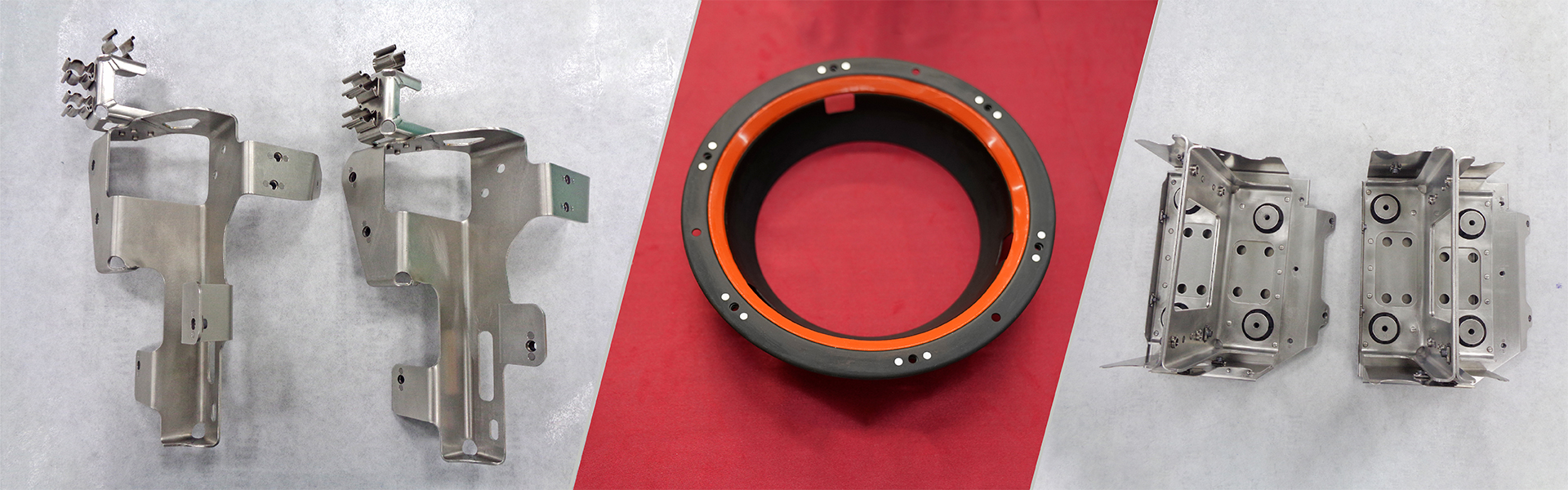

- Fully-automated & SCADA-controlled surface treatment line

- Soft metal – Aluminum Alloys

- Anodizing (4 m x 1 m x 1.3 m)

- Chromic Acid

- Boric Sulphuric Acid

- Tartaric Sulphuric Acid

- Sulphuric Acid

- Hard Anodizing & Chemical Conversion Coatings

- Alodine 1200

- Anodizing (4 m x 1 m x 1.3 m)

- Hard metals – Steel, Titanium, Inconel (Tank size 1.5 m x 0.9 m x 1.2 m)

- Passivation and Acid Pickling

- Two paint booths

- Primer and Top-Coat (Booth Size: 4 m x 1.3 m x 1 m)

Previous

Next

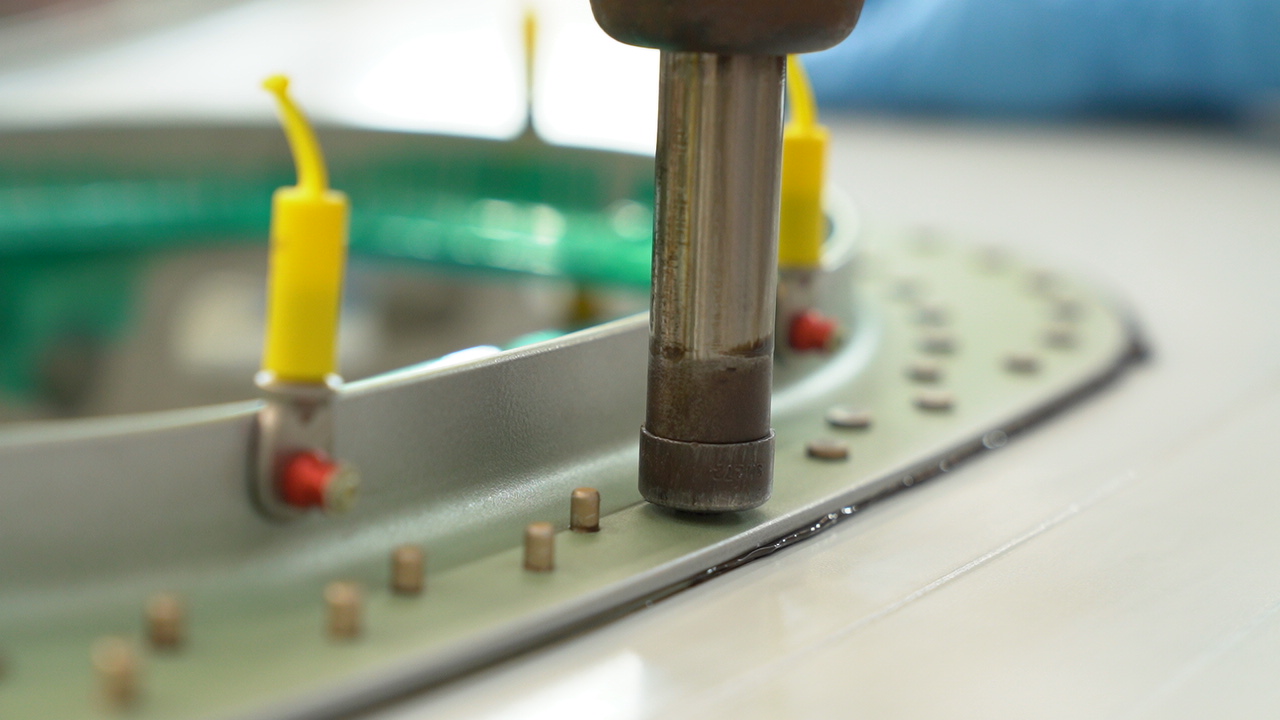

Assembly

- Assembly bay with Overhead EOT crane capacity

- Controlled-environment sealant application room

- Detail part equipping, production of sub-assemblies

- Door skin assemblies for single-aisle

- Nacelle inlet outer barrel assemblies for single-aisle

Previous

Next

Welding & Tube Bending

- TIG welding & Modular Glove Box with autonomous purification system for stainless steel, titanium components.

- 5axis bending for soft and hard alloy tubes with 6 to 38 mm dia and up to 2.6mm wall thickness.

Previous

Next

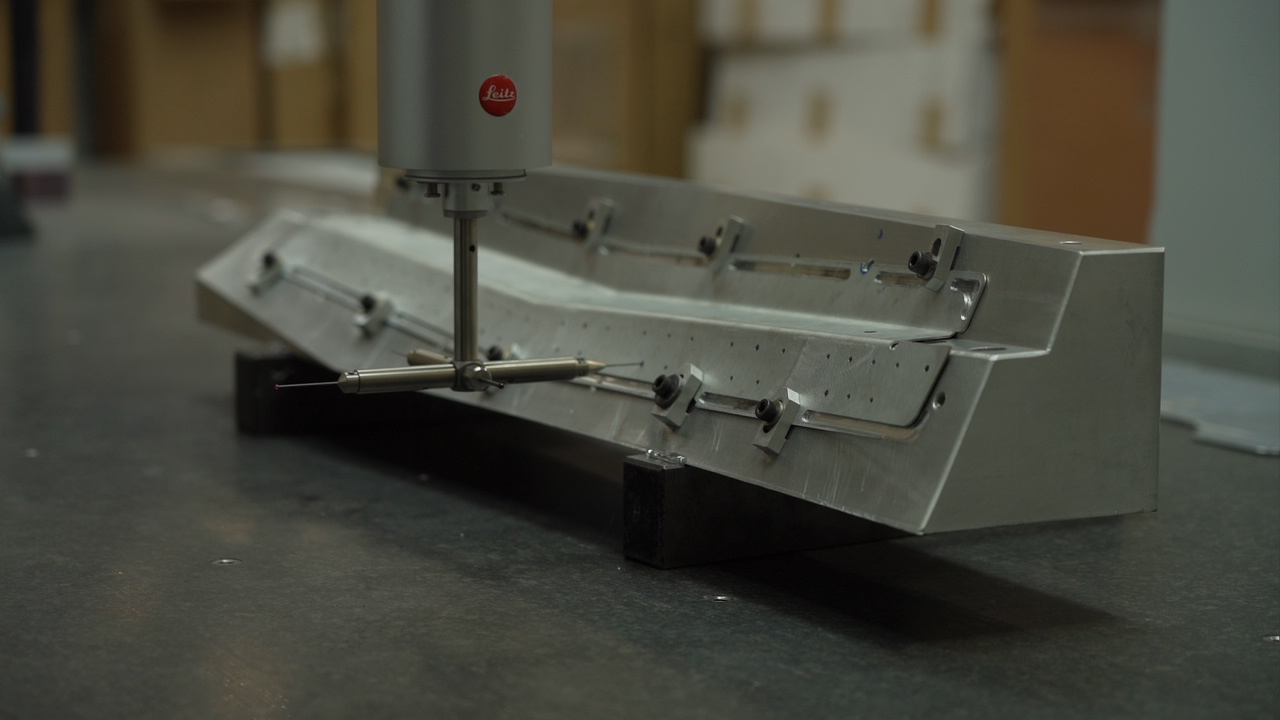

- Coordinate Measuring Machine (CMM) – 1.2 m x 3.0 m x 1.0 m

- Portable CMM – Faro

- Video Measuring Machine (VMM) – 0.5 m X 0.4 m X 0.2 m

- Hardness test (Rockwell & Vickers)

- OEM approved Chemical lab

- Non-Destructive Testing (NDT) – Fluorescent Penetrant Inspection

- Laser inspection

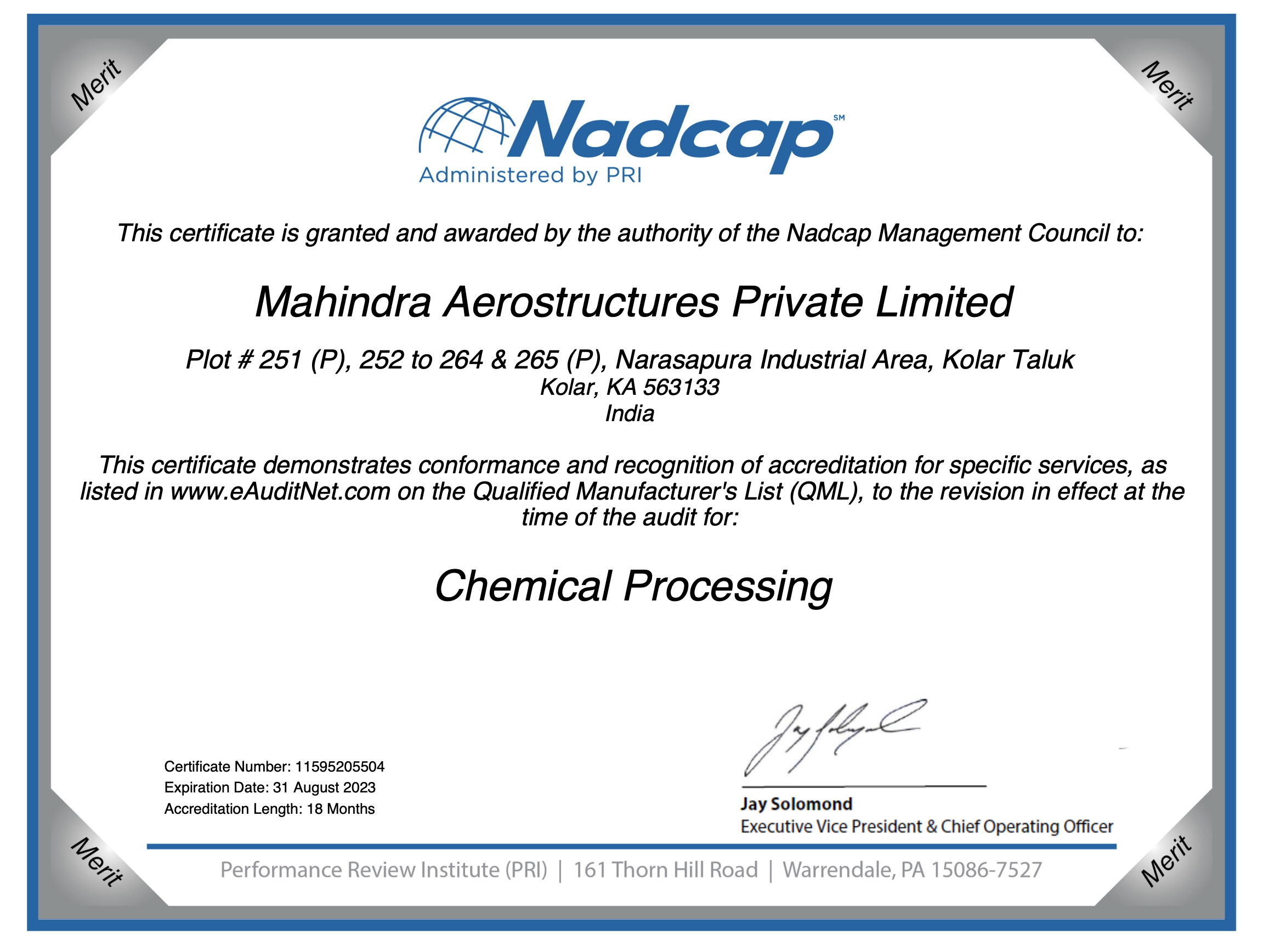

Certificates

Previous

Next

Previous

Next